Automation of a Water Treatment System Using PLC and HMI

Introduction

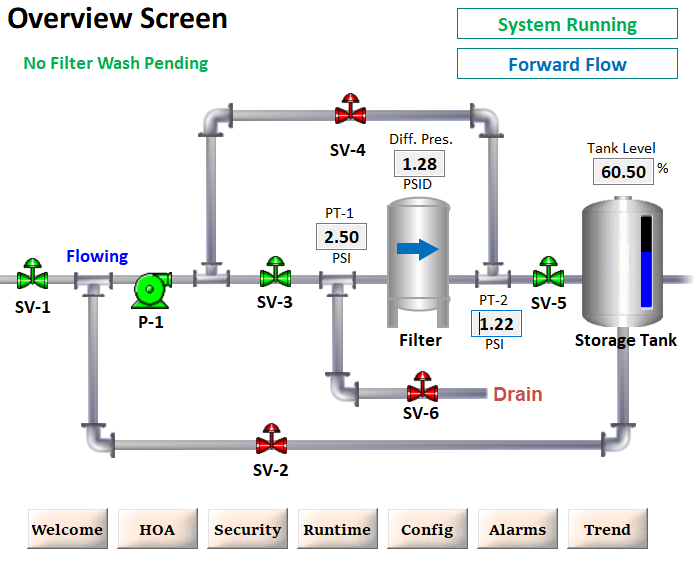

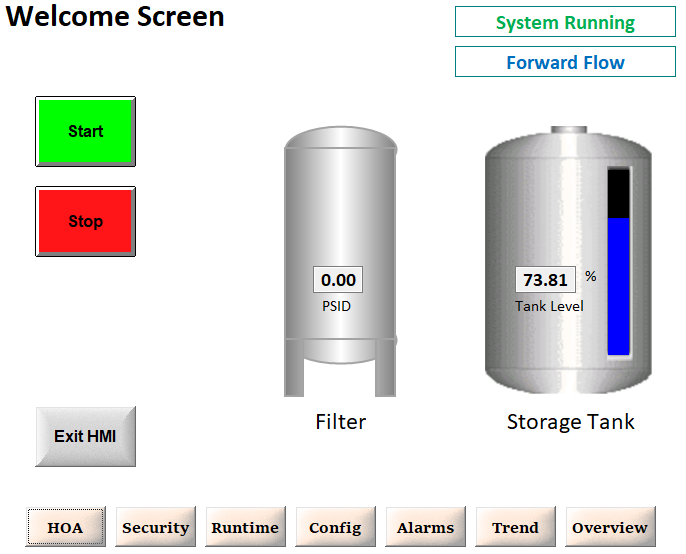

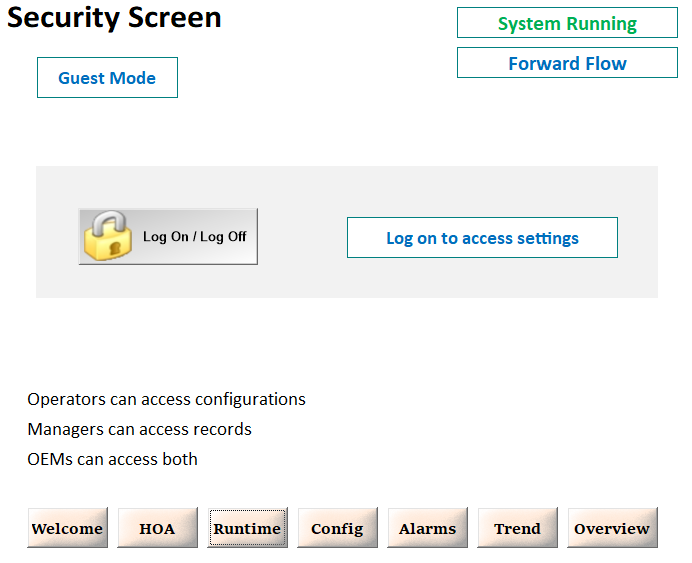

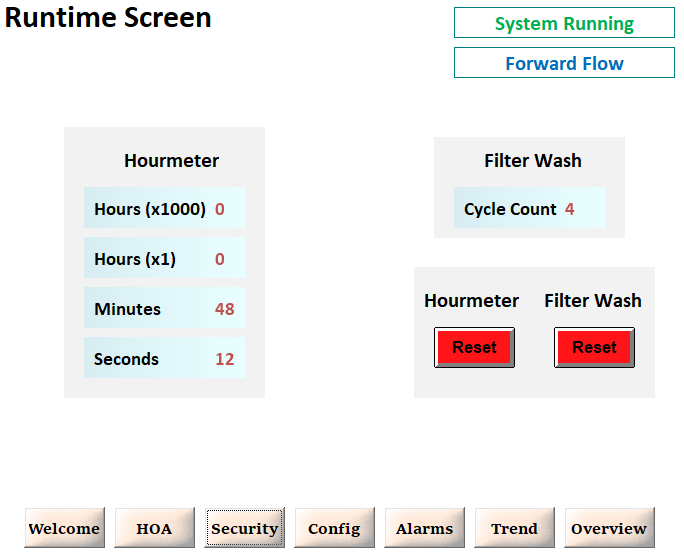

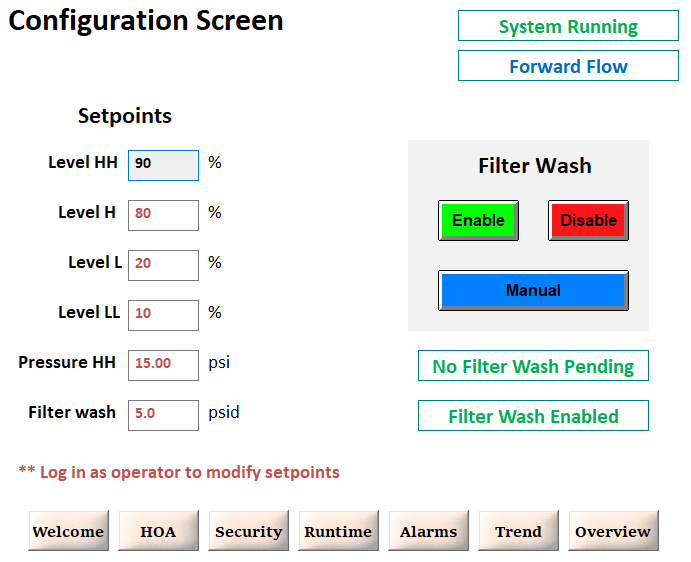

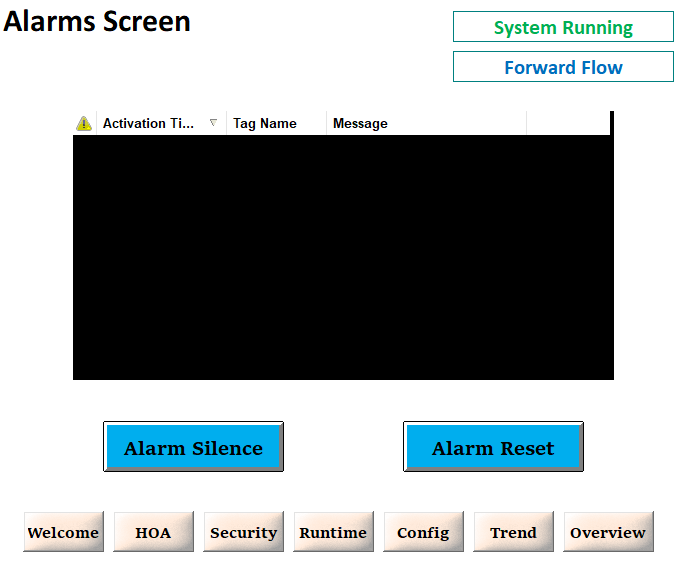

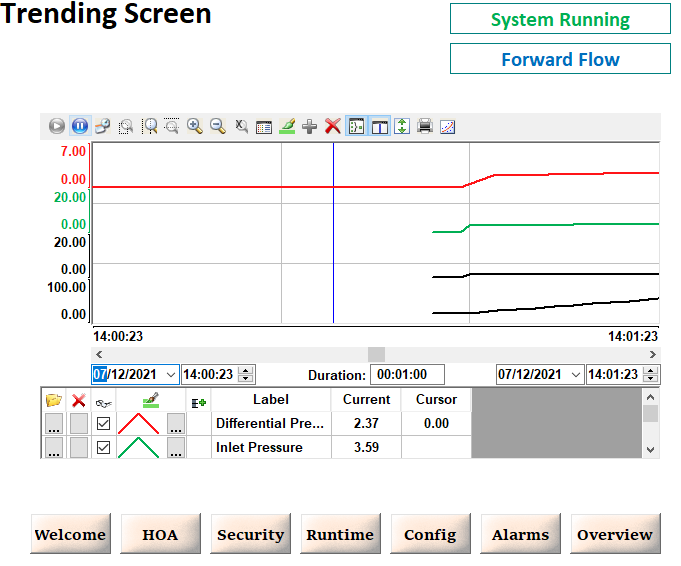

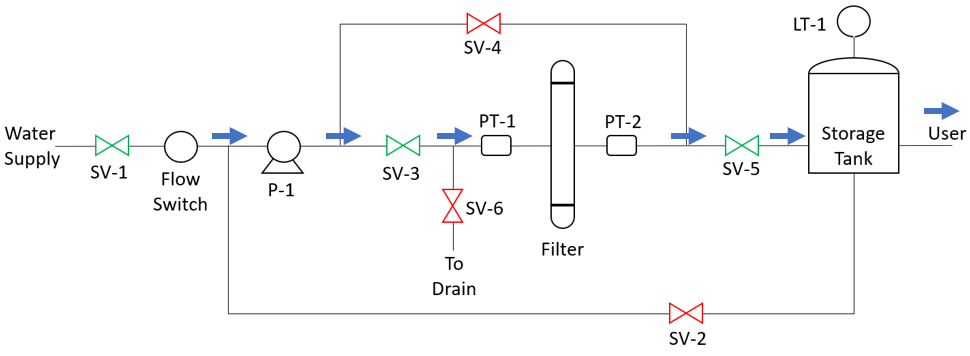

A PLC program has been written to automate a water treatment system along with an HMI for users to control the system

Input / Output

Three Analog Inputs -

inlet pressure transducer - measure the water pressure before entering into the filter

outlet pressure transducer - measure the water pressure after passing the filter

Water level transmitter - measure the water level inside the tank

One Digital Input -

Flow switch - ON or OFF the flow of water from the main water supply

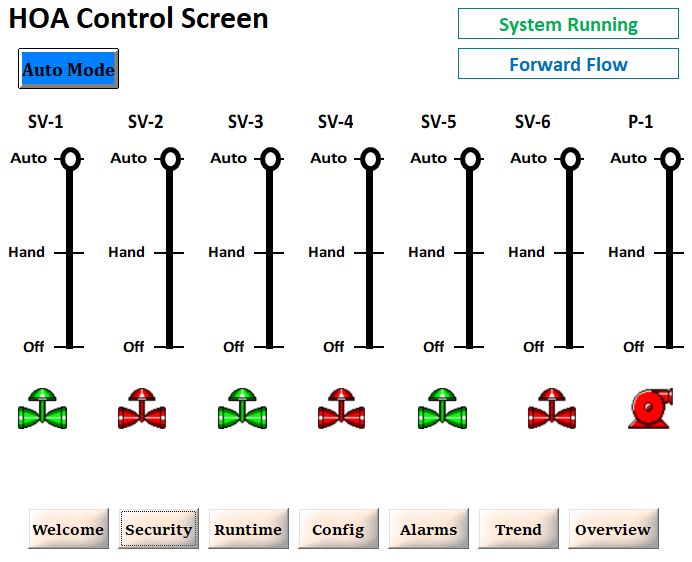

Seven Digital Outputs -

6 solenoid valves - control the direction of flow of water inside the pipes

1 pump - pump the water from the main water supply to the filter

Process

Forward Flow -

Water goes from main water supply to filter then the filtered water goes to the storage tank

Filter Wash Flow -

Clean the filter when the contaminant level inside the filter exceeds the threshold level

Forward Flow

State of Digital I/O –

- Pump (P-1) ON

- Solenoid valves ON (SV-1, SV-3, SV-5)

- Solenoid valves Off (SV-2, SV-4, SV-6)

Conditions –

- When system is running

- Stops when water level LT-1 > 80%

- Starts when water level LT-1 < 20%

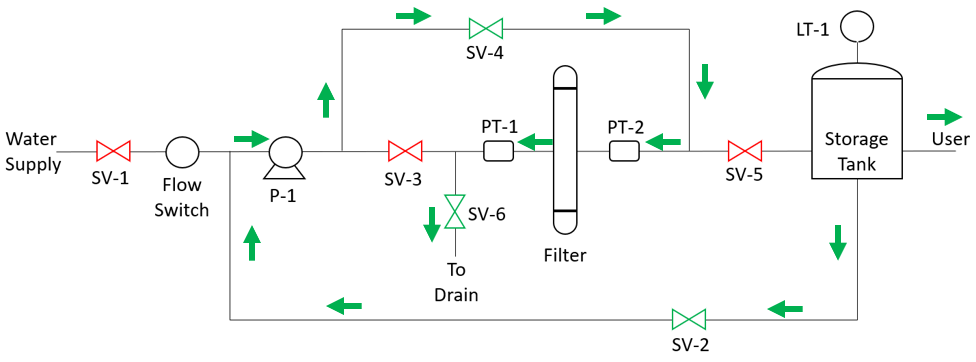

Filter Wash Flow

State of Digital I/O –

- Pump (P-1) ON

- Solenoid valves ON (SV-2, SV-4, SV-6)

- Solenoid valves Off (SV-1, SV-3, SV-5)

Conditions –

- When the inlet pressure is more than 5 psi then outlet pressure

- Starts when water level in the storage tank is more than 80%